杨小光 编译

In the cold open to Sunday's season premiere of Game of Thrones, patriarch and cold-hearted tactical mastermind Tywin Lannister personally oversees the work of one of the best blacksmiths in the kingdom. The task at hand: melting down the broadsword Ice, property of the now-dispatched Eddard Stark, to forge two new blades for the Lannisters.

在《权力的游戏》第四季第一集中,兰尼斯特家族族长和冷酷的战术大师泰温·兰尼斯特亲自监督了这个王国最好的铁匠的工作。这位铁匠的任务是融化已被斩首的艾德·史塔克的阔剑——寒冰,为兰尼斯特人锻造两把新剑。

Eddard Stark and his broadsword Ice

奈德·史塔克和他的阔剑寒冰

Besides the obvious metaphorical value of melting down your foe's weapon to make it your own, there's another driver behind Lord Tywin's action: Ice is one of the few remaining swords in the Game of Thrones universe known to be made of Valyrian steel, a mystical material that makes the best weapons around. But the secret of making this alloy has been lost to the ages. Only a handful of smiths in Westeros know how to reshape the material.

这个行为除了明显的隐喻:“熔化你敌人的武器,让它成为自己的”外,泰温公爵这样做还有一个原因:在《权力的游戏》中,寒冰剑是仅剩的几把用专门打造神兵利器的材料——瓦雷利亚钢制成剑。但是制造这种合金材料的秘密已经消失了很久。在维斯特洛,只有屈指可数的几个铁匠知道如何改造材料。

Does a real-life version of Valyrian steel, popularised by the Game of Thrones series, have the potential to revolutionise automotive markets?

美剧《权力的游戏》让“瓦雷利亚钢”火了,但是这种钢在现实生活中存在吗?(如若真的存在)它有可能改变汽车市场吗?

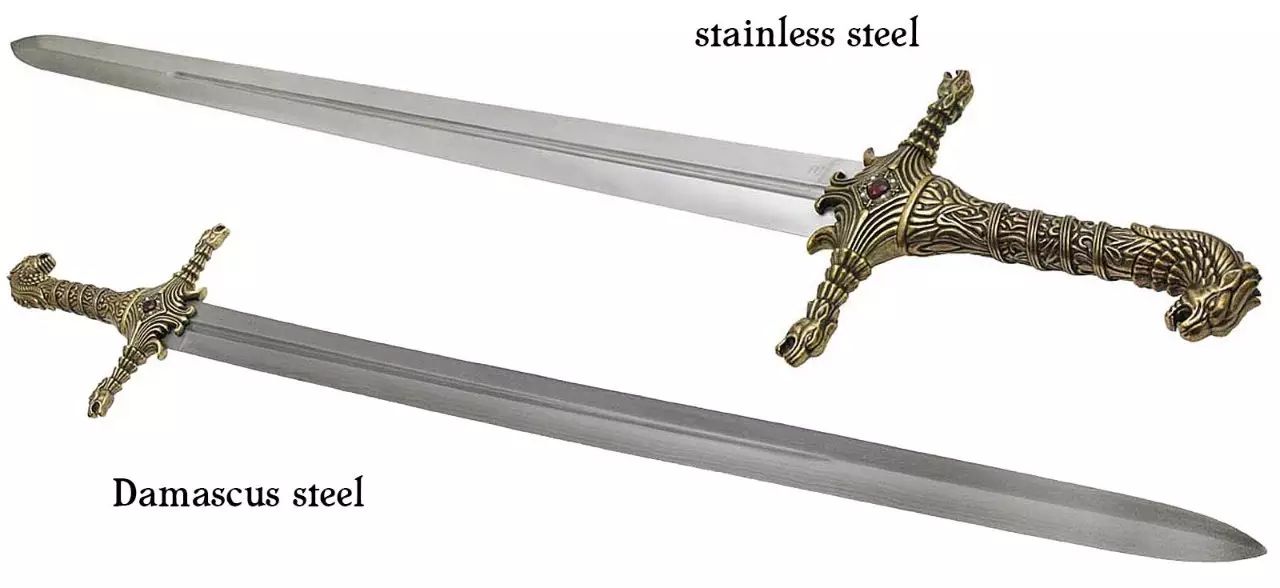

If you ask any Game of Thrones fan about a Valyrian steel sword, their eyes will likely mist over as they describe its exceptional sharpness, strength, lightness and distinct ripple patterns. Ask Professor John Verhoeven, a retired Iowa State University metallurgist, about the real-life equivalent – a Damascus steel sword – and you’ll receive the same, wistful response.

倘若你问:瓦雷利亚钢剑是什么样的?任何一个“冰火迷”都只能描述个大概:极其锋利、坚硬,寒光逼人,剑身还绣满各式花纹图案···然而现实生活在实际存在的、类似于瓦雷利亚钢剑的大马士革钢剑是什么样的?你要问美国爱荷华州立大学退休冶金学家——约翰·费尔赫芬教授这个问题时,的回答也不能让人完全满意。

“The surface of a Damascus steel sword has this beautiful distinct, wavy pattern,” he says. “But if you are able to cut one up and study its microstructure under a microscope you will see layers of carbide particles that look like the Milky Way; tiny white dots all clustered together.”

“大马士革钢剑的表面布满各式各样美丽的、波浪形的图案”,费尔赫芬教授说,“但是如果你从这种钢剑上切一块下来研究它的显微结构,你会看到层层的碳化物颗粒,有许多聚集在一起的小白点,看起来像银河。”

Be it fact or fiction, Verhoeven and many fans of the epic fantasy drama are dazzled by these legendary weapons. But for Verhoeven, his enduring passion follows a life-long commitment to solving the mystery of the Damascus steel sword.

不管是在现实还是在小说中,这些传奇般的兵器让费尔赫芬以及这部史诗奇幻剧的许多粉丝目炫不已。但对于费尔赫芬来说,他将自己毕生的精力都致力于研究大马士革钢剑的秘密。

Manufactured between the 3rd and 17th centuries, Damascus blades were prized for being so sharp they could cut a silk scarf in half as it fell to the ground. Yet, as Verhoeven points out, the last swords were made in the early 1800s and the formula for the steel soon died out.

大马士革剑大规模制造于公元3世纪到17世纪之间,其以刀刃极其锋利著称,以至于它可以将往下落的丝巾切成两半。然而正如费尔赫芬所言,最后的那批大马士革剑是在19世纪初制成的,从那时起大马士革钢的锻造工艺很快就失传了。

Reports indicate that the swords were made by forging small cakes of ‘wootz’ steel, manufactured in India. Here, craftsmen would melt iron and carbon-containing materials, such as charcoal, in a sealed crucible. The cooled and hardened ingots were then shipped to Damascus, where smiths would heat and hammer them to form the blade with its deadly properties and characteristic pattern.

有报道称,这些剑是在印度用小块的“乌兹钢”熔化锻造而成的。在这里,工匠们在一个密封的坩埚里熔化铁和含碳材料,比如木炭。随后,冷却、硬化的钢锭被运往大马士革。在那里,铁匠们将它们加热并进行锻打,使其剑刃锋利无比、花纹图案精美别致。

Recreating Damascus steel

Verhoeven spent much of the 1980s formulating a method to replicate this process, with blacksmith Alfred Pendray. And come the 1990s, the pair were consistently making Damascus-like blades via a forging and cyclic heating process, and using a cast iron called Sorel.

在20世纪80年代,费尔赫芬和铁匠阿尔弗雷德·彭德雷花费了大量时间来制定一种方法来复原这个过程。到了20世纪90年代,这对搭档一直在用锻造和循环加热索雷尔生铁(一种低锰生铁)的方法制造传说中的大马士革钢剑。

“Al’s technique was similar to what we learned ancient people had used,” explains Verhoeven. “Still, I was unable to figure out what was going on right away, until 1996, when I realised this steel contained impurities of vanadium.” Indeed, as the metallurgist highlights, impurities, such as vanadium, promote the alignment of carbides during ingot forging, leading to the banding patterns.

“阿尔弗雷德所用的方法和我们所知的古代人的做法类似。”费尔赫芬解释到,“尽管如此,我还是无法弄清到底发生了什么,然而直到1996年,我才意识到这钢中含有钒。”事实上,正如这位冶金学者所强调的,像钒这样的杂质,在铸锭过程中促进了碳化物的排列,从而导致了条带状花纹。

Yet despite success, Verhoeven’s method never made it out of the blacksmith’s forge. According to the metallurgist, their process was labour- and energy-intensive, and, as he adds: “It’s just way too expensive to be commercialised.”

然而,尽管理论上可以解释,但利用费尔赫芬的方法,这种钢却从未被铁匠锻造出来。根据冶金学者的说法,他们的制作过程是劳动密集型和能源密集型的,他还补充道:“商业化的成本太高了。”

Developing a super malleable steel

But Verhoeven has hardly been alone in his hot pursuit of the Damascus steel sword. In the early 1980s, Professors Jeffrey Wadsworth and Oleg Sherby from Stanford University were developing ultra-high carbon, super malleable steels with great strength, ductility and toughness.

但在对大马士革钢剑的狂热追求中,费尔赫芬绝非独自一人。20世纪80年代初,斯坦福大学的杰弗里·沃兹沃斯教授和奥列格·舍尔比教授正在开发超高碳、超韧性钢,这些钢种的强度大,延展性和韧性好。

The pair manufactured ring components and bevel gears from their ultra-high carbon steel, and were convinced the material held great potential in structural applications, including ultra-high strength sheet materials for automotive applications.

这对来自斯坦福大学的组合用超高碳钢制造了环形组件和锥齿轮,并确信该材料在结构应用中具备巨大的潜力,包括用于汽车的超高强度材料。

Around this time, the researchers also realised their material compositions coincided with that of Damascus steel swords. Given this, they went on to hone the ‘Wadsworth-Sherby’ method which reproduced super malleable steels with coarser and aggregated iron carbides to produce the distinct banding.

在这段时间里,研究人员也意识到他们的物质组成与大马士革钢剑正好吻合。考虑到这一点,他们继续改进了“沃兹沃斯 - 舍尔比”的方法,该方法可以用成分更粗复杂的聚合铁碳化物来生产出有明显的条带状的超韧性钢。

Their results hit the headlines, and they reckoned they had shown that ancient Damascus steel swords could have exhibited super malleable properties. But, again, commercialisation faltered.

他们的研究结果轰动一时,他们认为自己已经证明了古代大马士革钢剑可能具有超强的可延展性。但是,还不具备商业化的条件。

As Wadsworth, now president of US-based research organisation, Battelle, says: “Commercialisation of our ring components was intended by Sulzer Brothers of Switzerland, but the project was abandoned.“We gave it hell of a shot and did everything we could, but we got caught up in scaling up costs,” he adds.

“我们环组件的商业化是由瑞士苏泽兄弟公司设计的,但是这个项目被放弃了。”已成为美国巴特尔研究所所长的沃兹沃斯介绍说,“我们已竭尽所能,但实在承受不了不断高企的成本。”

A new phase of development

So, does the failure of past commercialisation attempts leave wootz steel and Damascus-like components firmly on the historical shelf? Given ongoing interest, perhaps not yet.

那么,过去的商业化尝试的失败是否会让“乌兹钢”和大马士革钢之类的刀具只能存在于被束之高阁的书籍里呢?考虑到目前公众对其持续高涨的兴趣,或许还没到说放弃的时候。

In the last few years, China-based researchers from the Central Iron & Steel Research Institute in Beijing, have used metallurgical computational software to analyse Damascus blade data and proposed mechanisms for the breathtaking bands.

在过去的几年,来自中国钢铁研究总院的研究人员使用冶金计算软件,分析了大马士革剑刃的数据,并提出了剑身花纹的形成机理。

Meanwhile, researchers from Technische Universität Dresden, Germany, have used transmission electron microscopy to pinpoint carbon nanotubes in a genuine Damascus sabre, that they believe could also be linked to the banding.

与此同时,德国德累斯顿科技大学的研究人员使用透射电子显微镜,在一个真正的大马士革军刀中精确定位出碳纳米管结构,他们认为这也可能与剑身表面的条带状物有关。

Researchers at Mälardalen University, Sweden, have produced several knife blades while Damasteel, Sweden, produces ‘Damascus patterned steel’, for knife manufacture. And archeometallurgists from The Wallace Collection, UK, are using neutron diffraction analysis (a non-destructive scanning method that has high penetration into materials) to determine how several ancient blades were made.

瑞典梅拉达伦大学的研究人员制造了几把刀片,而瑞典的达玛钢制造了“大马士革花纹钢”,用于制造刀具。来自英国华莱士收藏馆的考古学家们正在使用中子衍射分析(一种具有高渗透材料的无损扫描方法)来确定几种古代剑刃的制作方法。

For his part, Wadsworth is optimistic that, in time, the world will use Damascus-like steel for more than just the replication of ancient steel blades. “It would be interesting to compare the properties of modern steels going into cars with those of ultra-high carbon steel and see if weight savings can be gained through the superior strength of these steels,” he says.

沃兹沃斯乐观地认为,随着时间的推移,世界将会在各个领域使用像大马士革钢一样的钢铁材料,而不仅仅是对古老的刀具的复制。他说:“将现代的汽车用钢的性能与(古代用于制造大马士革钢剑的)超高碳钢进行比较,看看能否通过使用这些超高强度钢来减轻汽车重量,这将是一件有趣的事情。”

本文编译自文章《Forging Valyrian steel》 和《Can You Simply Reforge a Metal Like Valyrian Steel?》

新闻热线:010-64414265

广告热线:010-64442123

发行热线:010-64441858