正文

时长08:30

【老师介绍】

Karoly Szalai

布达佩斯技术大学

超过10年的工业自动化领域经验

专注于工业4.0相关的自动化解决方案

目前任SINNEO新络智能总经理

大家好!我是苏州新络智能技术有限公司的KarolySzalai卡洛伊。

今天我想给中国的中小企业带来一个引人深思的话题:

为什么需要投资工业物联网?

物联网和工业4.0不再是未来的概念。在2019年,它们被认为越来越主流。不仅是大企业,中小企业也需要适应和主动转型。

然而,数字化转型和工业物联网的成功实施,对于大型制造商或中小企业来说,需要采取不同的方式。在这段视频中,我想强调在制造业中实施工业物联网的重要性,以及中国中小企业在这一过程中所面临的典型障碍和恐惧。

我还将展示一个使用数据采集来评估工业物联网项目投资回报的案例研究。

在我们进行进一步讨论之前,我们需要定义

工业物联网

这个术语的实际涵义。

当今流行的流行词汇

物联网

是一个互联网概念,描述的是日常物理对象连接到互联网并能够通过其他设备识别自己。

过去我们通常用台式电脑、笔记本电脑或智能手机上网。简单地说,物联网可以将任何日常用品连接到互联网上,例如烤面包机、牙刷,甚至是生产设备。

那么工业物联网呢?

工业物联网

就是在制造业中使用物联网技术。工业物联网有时也被称为工业互联网。

工业物联网听起来很麻烦,那么中小企业为什么要关注呢?这个问题有两个原因:

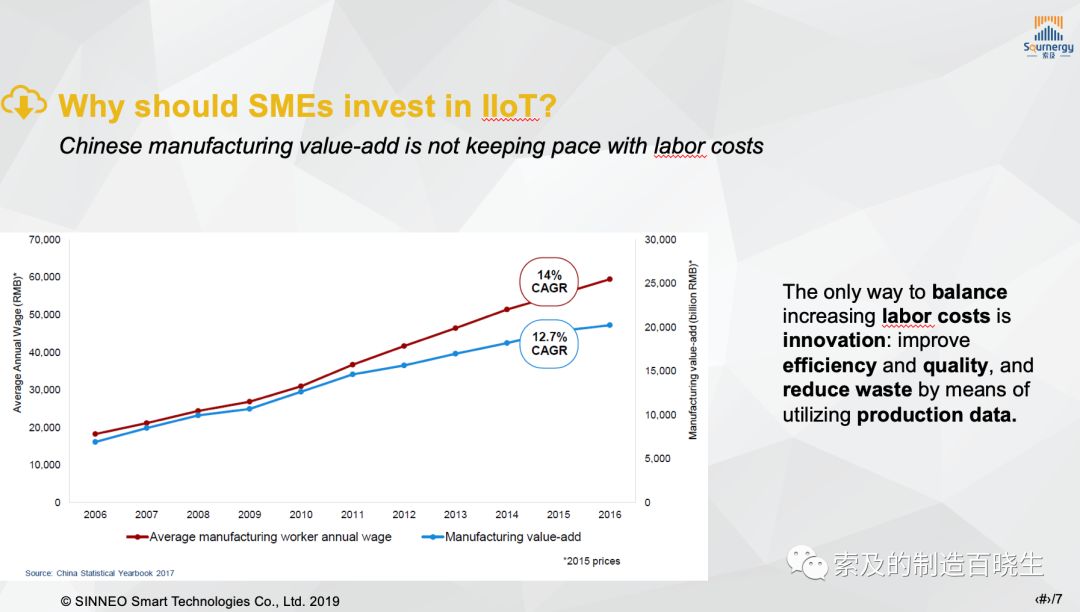

首先,中国制造业的增加值跟不上劳动力成本。实际上,这意味着工资的增长速度快于制造商的生产率。这种增加价值和劳动力成本之间的差距越来越大,导致外国中小企业将生产移出中国,中国中小企业失去了竞争力。

第二个根源是宏观经济环境。GDP增速放缓、中美贸易紧张等问题给中国制造业带来了越来越大的压力。大型企业的利润率较高,因此受到的影响较小,但中国中小企业制造商的利润率通常很低,经济动荡严重影响了它们的盈利能力。

那么出路是什么呢?其实这是显而易见的:提高生产率,降低成本,消除浪费。

创新和技术可以帮助做到这一点:利用在研讨会中生成的数据,从而获得对生产的当前状态的洞察和全面的概述。

如果它得到测量,它可以得到改善。就这么简单。

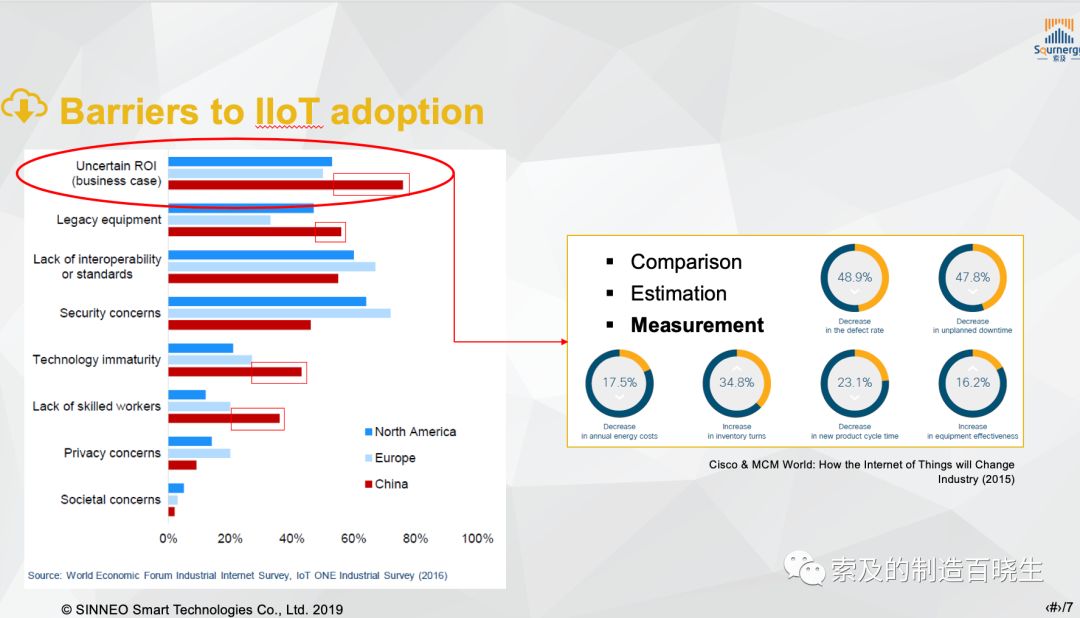

不过,对习惯现有制造业活动的人来说,引入新技术和新工艺可能非常具有挑战性。根据2016年世界经济论坛产业工业物联网调查,这些是制造商在尝试采用工业物联网技术时面临的主要障碍。

让我们仔细看看红色的条形图,这些条形图代表了来自中国的受访者的回答。这表明,中国企业最关心的是工业物联网应用的投资回报率不确定性。

中国企业似乎比欧洲或北美企业更担心这个问题。

这是一个合理的担忧,没有人想把钱白白浪费掉。如果以前从未应用过这些技术,那么确定一个工业物联网项目的投资回报率绝不是一件容易的事情。

这方面可能有三种不同的方法。

首先,可以将您的项目与在技术文献或其他来源中找到的类似业务案例进行比较。

或者,如果您能够从车间访问相关的历史生产数据,那么可能能够做一些粗略的估计。例如,如果您可以将生产机器的总停机时间减少10%,这种情况下在一年内可以节省多少?

此外,还有一种不太为人所知的方法:您实际上可以通过现场测算来评估工业物联网实现的投资回报率。

正是出于这个目的,我们在新络智能开发了一个名为mobileOEE的服务概念,它服务于两个目标:

1. 它支持决策者非常迅速地洞察真实的机器性能;

2. 它可以帮助评估昂贵的工业物联网项目的投资回报率,比如采用MES(制造执行)系统。

让我们来看看一个案例研究解释如何使用它。

一家紧固件制造商正面临着螺丝系统的问题。根据机器数据表和计算的周期时间,生产量应该比实际高得多。因此,在每一个生产班次中,生产数量都远远低于目标。

该系统由三台机器组成:螺丝机、自动送料机和在工位间传递紧固件的操作机器人。

工厂面临着投资提高生产能力的压力,但是他们不知道从哪里开始……

他们应该购买另一套同样的设备吗?或者只是用一个更快的机器人代替现有的设备?

对于这个任务,采用一个已安装的OEE监测系统将会非常昂贵和耗时,因此工厂决定尝试另一种方法。

他们转向mobileOEE解决方案,这是一种租赁服务,可以在任何时间段里使用。

该系统包括一个数据采集装置,它安装在螺丝系统附近,通过几个简单的I/O信号与设备通信。

在制造运行过程中,设备记录每台连接机器的时间序列OEE数据,也记录操作员手工输入的数据。例如,停机原因或者产品编号。同时,工程师可以通过web浏览器实时监测OEE值。

在租期结束时,工厂拥有真实的生产数据,以识别流程瓶颈并支持关键的工业物联网投资决策。

最后,作为中小企业的一个关键点。目前被称为工业4.0的技术趋势,是制造业技术的必然进展,而不仅是一场即将消退的炒作。

我们已经不再问智能制造”何时“到来的问题。现在唯一的问题是你能多快适应。

感谢大家的关注!

欲知更多的信息,请浏览我们的网站:sinneo-tech.com。

以下为英文原文

Hi! This is Karoly Szalai from SINNEOSmart Technologies. Today I would like to present some food for thought forChinese Small and Middle Size Enterprises: why should they invest in IndustrialIoT? IoT and Industry 4.0 are not futuristic concepts anymore, in 2019 theseare considered more and more mainstream. Not only large corporations, but alsoSMEs need to adapt and take initiatives to transform their manufacturing.

However, the successful implementation ofdigital transformation and IIoT call for different approaches in case oflarge manufacturers or SMEs. In this video I would like to highlight theimportance of IIoTimplementation in manufacturing, and the typical barriers and fears thatChinese SMEs face in this process. I am also going to demonstrate a case studyabout using data acquisition to estimate the Return On Investment of an IIoTproject.

But before we go into any furtherdiscussions, we need to define what the term Industrial IoT actually means.

The popular buzzword of our days,Internet of Things, is a computing concept that describes the idea of everydayphysical objects being connected to the Internet and being able to identifythemselves to other devices. In the past we usually connected to the Internetwith our desktop PCs, laptops or smartphones. Simply put, IoT enables toconnect literally any everyday objects to the Internet, just like toasters,toothbrushes, or even production assets.

How about Industrial IoT? Industrial IoT(or shortly IIoT) issimply the use of IoT technologies in manufacturing. IIoT issometimes also referred to as the Industrial Internet.

OK, so IIoT sounds like a lot of hassle, then whyshould SMEs care at all? The issue is rooted in 2 factors.

First, Chinese manufacturing value-add isnot keeping pace with laborcosts. Practically it means, that the salaries increase faster than theproductivity of manufacturers. This growing gap between value-add and laborcosts causes foreign SMEs to take their production out of China, and ChineseSMEs to lose their competitiveness.

The second factor is the macroeconomicenvironment. Issues like the slowing GDP growth or the China-US trade tensionsput an ever growing pressure on the Chinese manufacturing industry. Largeenterprises apply higher profit margins so they are less affected, but ChineseSME manufacturers usually operate with very narrow margins, so economicturbulences seriously bite into their profitability.

Then what is the way out? Actually it isobvious: increase productivity, reduce costs and eliminate waste. Innovationand technology can help exactly with that: leverage the data generated in yourworkshop, in order to gain insights and a holistic overview of the currentstate of your production.

If it gets measured, it can be improved.As simple as that.

Introducing new technologies andprocesses in your accustomed manufacturing life can be very challenging though.Based on the World Economic Forum Industrial Internet Survey from 2016, theseare the main barriers manufacturers face when trying to adopt IIoTtechnologies.

Let’s take a closer look at the redcolour bars, as those represent the answers of the survey respondents fromChina. It shows that the number oneconcern for Chinese companies is the uncertain ROI of IIoTadoption. It seems Chinese businesses are much more worried about it than theirEuropean or North American counterparts.

Well, this is a valid concern, nobodylikes throwing out money through the window. And it is far from trivial todetermine the ROI of an IIoTproject, if you had never applied such technologies before.

Here, there might be 3 differentapproaches. You might compare your project with a similar business case thatyou found in technical literature or other sources. Or, if you are able toaccess relevant historical production data from your shopfloor,then you might be able to do some rough estimation. For example, if you canreduce the total downtime of a production machine by 10%, how much can you savewithin 1 year?

Furthermore, there is also a not sowell-known approach: you can actually estimate the ROI of IIoTimplementation with onsite measurement.

Exactly for this purpose have wedeveloped at SINNEO a service concept called Mobile OEE, that serves 2 goals:

1.itsupports decision makers to gain insights very quickly into the real machineperformance; 2.itprovides help to estimate the ROI of costly IIoT projects, like the adoption of aManufacturing Execution System.

Let’s see a case study how it works. Afastener manufacturer is facing issues with their thread rolling system.According to the machine datasheets and the calculated cycle time, theproduction throughput is supposed to be much higher, than it actually is. So inevery work shift the production quantity stays far below the targets.

The system consists of 3 machines: thethread rolling machine, an automated screw feeder, and a handling robot thattransfers the fasteners between the stations.

The factory is facing pressure toundertake some kind of investment to increase the production throughput, butthey are clueless where to start… Should they buy a complete copy-system tooperate in parallel? Or just replace the robot with a faster one?

It would be too costly and time consumingto adopt an installed OEE monitoring system for this task, so the factorydecided to try another approach. They turned to the Mobile OEE solution, whichis a rental service, for any chosen time period. The system includes ameasurement device, which is installed near the thread rolling system, andconnected to the equipment via a few simple I/O signals. During manufacturingoperation, the device records time-series OEE data from each connectedmachines, and also records manual data input from the operators. For example,reasons for downtime or eventually product IDs. Meanwhile the engineers canmonitor the OEE values in real-time via their web browser.

At the end of the rental period, thefactory has real production data on hand to identify process bottlenecks andsupport critical IIoTinvestment decisions.