中文导读

增材制造(俗称3D打印)技术是指以数字模型文件为基础,运用树脂或金属等可粘合材料,通过逐层打印的方式来构造物体的技术。该技术具有数字化制造、快速成型、可迅速为客户提供定制产品、方便成型复杂形状制件等突出特点。随着各种新型打印技术的不断涌现,3D打印技术有望克服其不适用于大批量生产的缺点,从而使得未来的制造业领域发生深刻变革。

3D printers will shape the factory of the future

MANUFACTURING advances often take time to catch on. Only later does their real significance become apparent. The flying shuttle, invented in 1733 by John Kay, a British weaver, allowed the production of wider pieces of cloth. Because its movement could be mechanised, the shuttle later became one of the innovations which paved the way for the Industrial Revolution. In 1913 Henry Ford brought motoring to the masses by making his Model T on a moving assembly line; but it was Ransom Olds, a decade earlier, who had come up with the idea of an assembly line to boost production of the Olds Curved Dash. Throughout the 1980s factory bosses scratched their heads over Taiichi Ohno’s Toyota Production System and its curious methods, such as the just-in-time delivery of parts. Now it is the global benchmark for factory efficiency.

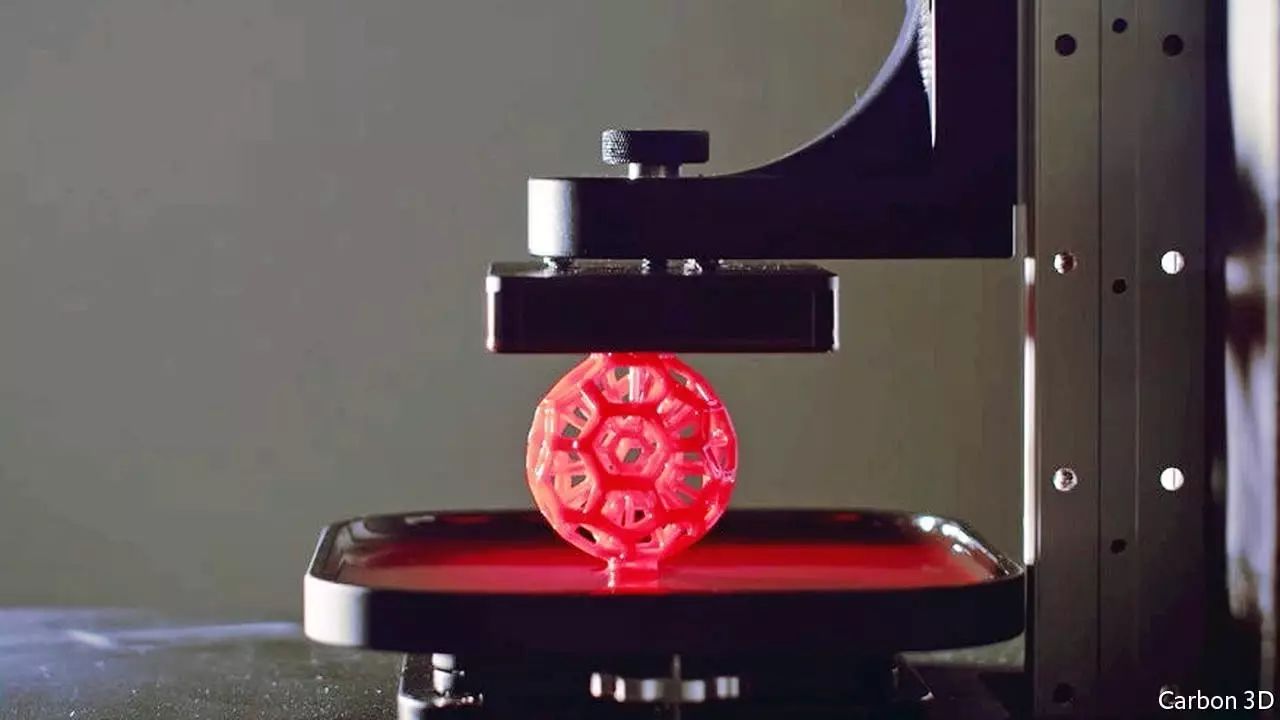

What, then, to make of the potential of Chuck Hull’s invention in 1983 of “stereolithography”? Mr Hull is the co-founder of 3D Systems, one of a growing number of firms that produce what have become known as 3D printers. These machines allow a product to be designed on a computer screen and then “printed” as a solid object by building up successive layers of material. Stereolithography is among dozens of approaches to 3D printing (also known as additive manufacturing).

Printing has become a popular way of producing one-off prototypes, because changes are more easily and cheaply made by tweaking a 3D printer’s software than by resetting lots of tools in a factory. That means the technology is ideal for low-volume production, such as turning out craft items like jewellery, or for customising products, such as prosthetics. Dental crowns and hearing-aid buds are already being made by the million with 3D printers. Because it deposits material only where it is needed, the technology is also good at making lightweight and complex shapes for high-value products ranging from aircraft to racing cars. GE has spent $1.5bn on the technology to make parts for jet engines, among other things.

But sceptics still rule the roost when it comes to goods made in high volumes. They say that 3D printers are too slow and too expensive—it can take two days to create a complex object. Unlike the techniques pioneered by Kay, Olds and Ohno, additive manufacturing will never revolutionise mass production. Such scepticism looks less and less credible.

Some of the new methods of 3D printing now emerging show that its shortcomings can be overcome. Adidas, for one, has started to use a remarkable form of it called “digital light synthesis” to produce the soles of trainers, pulling them fully formed from a vat of liquid polymer. The technique will be used in a couple of new and highly automated factories in Germany and America to bring 1m pairs of shoes annually to market much more quickly than by conventional processes. A new technique called bound-metal deposition has the potential to change the economics of metal printing, too, by building objects at a rate of 500 cubic inches an hour, compared with 1-2 cubic inches an hour using a typical laser-based metal printer.

Layers of meaning